| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Victory |

| Model Number : | Sondex Series |

| Certification : | ISO |

| Price : | 50 - 500pieces $5-10 |

| Payment Terms : | T/T |

| Supply Ability : | 100000 pieces per month |

| Delivery Time : | 15 days |

| MOQ : | 50 pcs |

Product Description

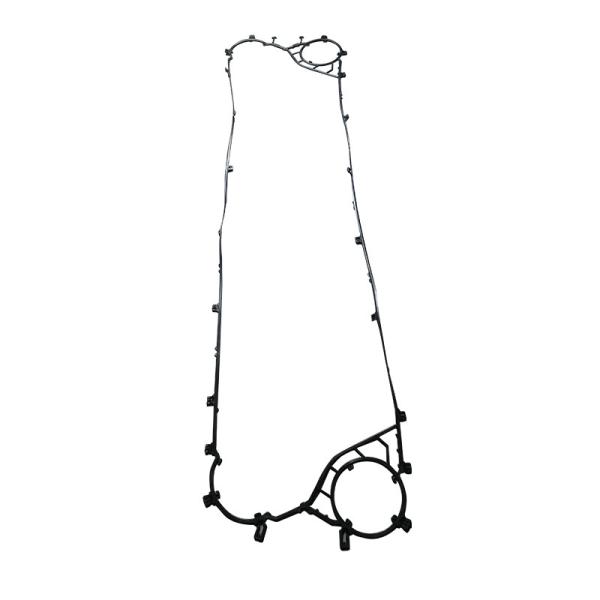

Heat Exchanger Gasket/Pad for Sondex Plate Heat Exchangers:

1.Heat exchanger gaskets, commonly referred to as O-rings, are compact components widely used for effective sealing purposes. They are versatile and can be employed for both static and dynamic sealing applications.

2.Manufactured from soft rubber materials, these gaskets possess the capability to deform and retain their shape even after compression. This deformation creates contact pressure, effectively blocking any potential leakage paths and ensuring a dependable seal.

3.In the specific context of plate heat exchangers, the sealing gasket plays a crucial role in maintaining the overall integrity and optimal performance of the heat transfer equipment. It directly influences the temperature limits at which the heat exchanger can operate and also affects its pressure capacity.

4.The primary objective of the gasket is to establish a secure seal, effectively preventing any undesired leakage of the heat transfer medium into the surrounding environment. Additionally, it serves as a barrier to prevent cross-contamination between different materials being processed within the heat exchanger.

| Brand/Maker | Model |

| Sondex | S1,S4,S4A,S7A,S8,S8A,S9A,S14,S14A,S17,S19A,S20A,S21A, S22A,S31A,S22,SW26,S37,SW40A,S41,S41A,S42,S42A,S62, S43,S47,SN51,S52,S64,S65,S81,S100,S121,SF123,SF160 |

Gasket Material:

| Material | Operating Temperature Range | Usage conditions |

| Nitrile Gaskets | ≤135℃ | Resistant to mineral, animal, vegetable oil and other non-polar media |

| Hydrogenated Nitrile Gaskets | -5℃-150℃ | Resistant to sulfur-containing crude oil, H2S-containing mixed media, high-temperature edible oil and other non-polar media |

| EPDM Gaskets | ≤160℃ | Resistant to hot water, water vapor, edible beverages, and high-temperature sterilization of milk |

| Solvent-based EPR Gaskets | -20℃-150℃ | Polar solvents and many other good solvents, such as lipid solvents. Dilute inorganic acids, alkalis, etc. |

| Universal Viton Gaskets | ≤180℃ | Non-polar mineral oil, lubricating oil and other alcohol-containing fuels |

| Special Fluorine Rubber Gaskets | 30℃-130℃ | Inorganic oxygen-containing acids such as high-concentration acids and bases |

Manufacturing process of plate heat exchanger gaskets.

1.The rubber compounding process marks the initial stage, where a precise mixture of raw and auxiliary materials is created according to the specified formula requirements.

2.Following that, the rubber material is shaped into strips using extruder equipment, forming the rubber material blank.

3.The subsequent step involves compression molding. In this process, the unvulcanized rubber strip is inserted into a heated mold cavity, which is then closed to initiate vulcanization. This compression molding takes place within press equipment, resulting in the production of the rubber sealing gasket.

4.After molding, the gasket undergoes post-vulcanization. This stage entails placing the molded and vulcanized gasket in a stationary state within an oven, allowing the vulcanization process to reach its final completion.

5.Lastly, the finished product inspection phase is implemented. During this step, a sampling of finished gaskets is subjected to thorough testing in accordance with the established process standards.

Installation method

Plate heat exchanger sealing gaskets can be divided into 3 forms according to the installation method on the heat exchange plates:

1. Direct sticking type: After applying sealant on the sealing gasket, it is directly glued into the installation groove of the heat exchange plate.

2. Plastic nail inlaid type: The heat exchange plate is designed with assembly holes, and rubber nails are designed on the side of the sealing gasket. After the sealing gasket is placed in the installation slot, the rubber nails are embedded in the assembly holes.

3. Snap-on type: There are buckles on the side of the sealing gasket, and the buckles are used to buckle the sealing gasket onto the heat exchange plate.

The sealing gasket uses different types of rubber according to different media and operating temperatures.

Q&A

Q1: Does the gaskets product come with a warranty?

A1: Gasket are consumable accessories, and the replacement cycle is generally determined according to the specific conditions of use by the customer. It is related to the use environment, medium, temperature, etc. Usually we recommend purchasing more for replacement and backup purposes.

Q2: Is there a discount available for wholesale or bulk purchases?

Answer: Yes, we offer discounts for wholesale and bulk purchases. If you are interested in purchasing a large quantity of items or engaging in wholesale business, please contact our wholesale department or customer service team for information regarding wholesale discounts and minimum purchase quantities.

|