| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | GEA |

| Model Number : | VT04、VT10、VT20、VT40、VT80、VT405、VT2508、N40、FA184、NT50、NT100T、NT100M NT100X、NT150S、NT150L、NT250S、NT250M、NT250L、NT350S、 NT350M、NT500 |

| Certification : | ISO SGS |

| Price : | 50 - 500pieces $20-$30 |

| Payment Terms : | T/T, L/C, Western Union, |

| Supply Ability : | 50000pcs per month |

| Delivery Time : | 15 days |

Product Description

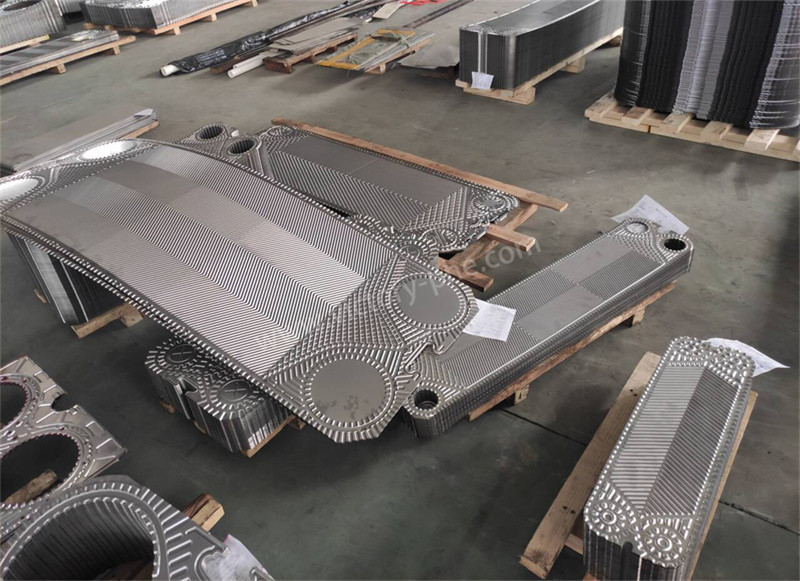

High Thermal Conductivity Hastelloy Nickel 0.6mm Heat Exchanger Plates For GEA PHE

GEA Heat Exchanger Plates

| Brand | Model |

GEA | VT04,VT10,VT20,VT40,VT80,VT405,VT2508,N40,FA184,NT50,NT100T, NT100MNT100X,NT150S,NT150L,NT250S,NT250M,NT250L,NT350S, NT350M,NT500 |

| Material | Specification |

| Stainless Steel | SUS304 316 316L 310S 904 |

| Titanium and titanium-palladium alloy | TAi TAi-Pd |

| Hastelloy | C276 D205 B2G |

| Nickel | Ni200 Ni201 |

| Molybdenum | 254 |

Plate heat exchanger plate thickness configuration

Applacations

| Plate material | Suitable for fluids |

| Stainless steel (SUS304.316, etc.) | Purified water, river water, edible oil, mineral oil |

| Titanium and titanium palladium (Ti, Ti-Pd) | Sea water, salt water, salt compounds |

| 20Cr,18Ni,6Mo(254SMO) | Dilute sulfuric acid, dilute salt aqueous solution, inorganic aqueous solution |

| Nickel (Ni) | High temperature, high concentration caustic soda |

| HASTELLOY alloy (C276, D205, B2G) | Concentrated sulfuric acid, hydrochloric acid, phosphoric acid |

Production Process:

|