| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Vicarb |

| Model Number : | V4、V8、VU8、V13、V20、V28、V45、V60 |

| Certification : | ISO SGS |

| Price : | 50 - 500pieces $21-$30 |

| Payment Terms : | T/T, L/C, Western Union, |

| Supply Ability : | 50000pcs per month |

| Delivery Time : | 15 days |

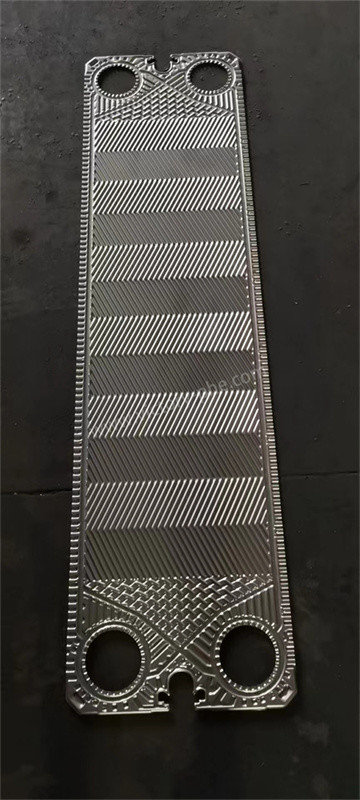

Heat Exchanger Plates

Heat Exchanger Gasket Plate Sheets In Stainless Steel, Titanium, And Nickel Alloy

The manufacturing process of heat exchanger plates typically involves the stamping or pressing of plates using various materials such as stainless steel, titanium, nickel alloys, and even certain plastics. The selection of these materials is based on considerations such as thermal conductivity, corrosion resistance, and compatibility with the fluids used in the heat exchanger.

Heat exchanger plates commonly utilize the following materials:

1. Stainless Steel: Renowned for its corrosion resistance and durability, stainless steel is suitable for a wide range of applications.

2. Titanium: Exhibiting excellent corrosion resistance, titanium is particularly suitable for aggressive environments.

3. Nickel Alloys: Nickel alloys offer good resistance to high temperatures and aggressive chemicals, making them suitable for demanding operating conditions.

4. Copper Alloys: Copper alloys are known for their high thermal conductivity, making them efficient for heat transfer applications.

Advantages of using different materials in heat exchanger plates are as follows:

1. Stainless Steel: Offers good corrosion resistance, durability, and cost-effectiveness.

2. Titanium: Provides excellent corrosion resistance, is lightweight, and has a high strength-to-weight ratio.

3. Nickel Alloys: Exhibits high-temperature resistance and corrosion resistance.

4. Copper Alloys: Possesses superior thermal conductivity for efficient heat transfer.

Disadvantages of using these materials are as follows:

1. Stainless Steel: Has lower thermal conductivity compared to some other materials.

2. Titanium: Comes with a higher cost compared to some other materials.

3. Nickel Alloys: Carries a higher cost and may not be suitable for all applications.

4. Copper Alloys: Can be susceptible to corrosion in certain environments.

The advantages and disadvantages of these materials depend on the specific application and operating conditions of the heat exchanger.

| Brand | Model |

| Vicarb | V4,V8,VU8,V13,V20,V28,V45,V60 |

| Material | Specification |

| Stainless Steel | SUS304 316 316L 310S 904 |

| Titanium and titanium-palladium alloy | TAi TAi-Pd |

| Hastelloy | C276 D205 B2G |

| Nickel | Ni200 Ni201 |

| Molybdenum | 254 |

Heat Exchanger Plates material

1. Stainless steel (SUS304 and SUS316L) is suitable for applications involving purified water, river water, food oil, and mineral oil due to its corrosion resistance and compatibility.

2. Industrial pure titanium and titanium-palladium alloy (Titanium and Palladium) are recommended for use with sea water, salt water, and salt compounds due to their exceptional corrosion resistance.

3. Hastelloy alloy is specifically designed for handling concentrated sulfuric acid, hydrochloric acid, and phosphoric acid, making it an excellent choice for applications requiring resistance to these corrosive substances.

4. Nickel is suitable for high-temperature and high-concentration caustic soda applications due to its ability to withstand harsh conditions at elevated temperatures and concentrations.

Q&A

1. Q: Are you a manufacturer or trading company?

A: We are a professional manufacturer of plate heat exchangers, plates, gaskets, plate mould with 18 years' experience.

Q: Can I customize samples of heat exchanger plates?

A: Yes,we welcome sample order to test and check quality.

|