| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | |

| Model Number : | M3、M6、M6-D、M6M、M6MC、M10B、M10M、M15B、M15M、M15MC、M20M M20B、MX25B、MX25M、M30、TS6、TL6B、TS20、TL10B、TL10P、T20B、T20M、T20P、TL35B P16、P26、P36、AK20、JWP26、JWP36、M6MW、M10BW、MK15BW |

| Certification : | ISO SGS |

| Price : | 50 - 500pieces $20-$30 |

| Payment Terms : | T/T, L/C, Western Union, |

| Supply Ability : | 50000pcs per month |

| Delivery Time : | 15 days |

Product Description

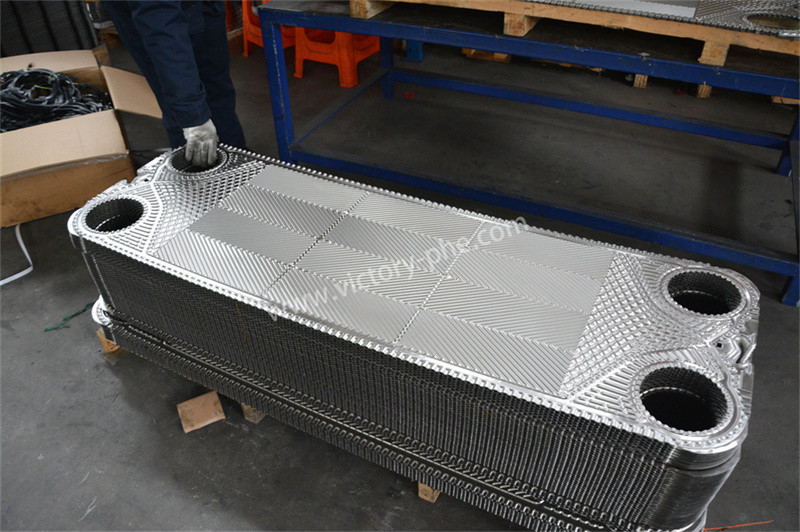

How To Maintenance M6,M6M,M6MC Heat Exchanger Plate With New Replacement Plate?

How to maintenance the plate heat exchanger?

To maintain a plate heat exchanger, follow these general steps:

Regular Cleaning: Clean the plates and gaskets regularly to prevent fouling and maintain efficient heat transfer. Use appropriate cleaning solutions and methods recommended by the manufacturer.

Inspection: Inspect the plates, gaskets, and frame for any signs of wear, corrosion, or damage. Replace any damaged components promptly to ensure optimal performance.

Tighten Connections: Check and tighten any loose bolts or connections to prevent leaks and ensure the integrity of the heat exchanger.

Monitor Performance: Regularly monitor the performance of the heat exchanger by checking temperature differentials, flow rates, and pressure drops. Any significant changes may indicate a problem that needs attention.

Schedule Maintenance: Follow a maintenance schedule provided by the manufacturer. This may include periodic inspections, cleaning, and replacing worn-out parts to prevent downtime and extend the life of the heat exchanger.

By following these maintenance practices, you can ensure that your plate heat exchanger operates efficiently and effectively for an extended period.

1. Stainless steel SUS304 SUS316L

Purified water, river water, food oil, mineral oil

2. Industrial pure titanium and titanium-palladium alloyTi tanium

and Pal ladium

Sea water, salt water, salt compounds

3. Hastelloy Alloy

Concentrated sulfuric acid, hydrochloric acid, phosphoric acid

4. Nickel

High temperature and high concentration caustic soda

The advantages of using stainless steel plates in a plate heat exchanger include:

Corrosion Resistance: Stainless steel plates are highly resistant to corrosion, making them suitable for a wide range of applications, including those involving corrosive fluids.

Hygienic Properties: Stainless steel is easy to clean and maintain, making it ideal for applications where hygiene is crucial, such as in the food and pharmaceutical industries.

High Strength: Stainless steel plates have high strength and durability, ensuring a longer service life and resistance to mechanical damage.

Temperature Resistance: Stainless steel can withstand high operating temperatures, making it suitable for applications where heat resistance is essential.

Compatibility: Stainless steel plates are compatible with a variety of fluids and are suitable for use in diverse industrial processes.

| Brand | Model |

M3,M6,M6-D,M6M,M6MC,M10B,M10M,M15B,M15M,M15MC,M20M M20B,MX25B,MX25M,M30,TS6,TL6B,TS20,TL10B,TL10P,T20B,T20M,T20P,TL35B P16,P26,P36,AK20,JWP26,JWP36,M6MW,M10BW,MK15B |

| Material | Specification |

| Stainless Steel | SUS304 316 316L 310S 904 |

| Titanium and titanium-palladium alloy | TAi TAi-Pd |

| Hastelloy | C276 D205 B2G |

| Nickel | Ni200 Ni201 |

| Molybdenum | 254 |

The advantages of ALFA heat exchanger plates compared to competitors' products include:

1. High Quality: ALFA heat exchanger plates are renowned for their

high-quality materials and manufacturing processes, ensuring

durability and reliability.

2. Technological Innovation: ALFA continuously innovates its

technology, providing leading heat exchange solutions to meet the

needs of different industries and applications.

3. Efficiency: ALFA heat exchanger plates offer high heat transfer

efficiency, helping to optimize the system's energy efficiency.

4. Sustainability: ALFA is committed to sustainability, offering

environmentally friendly heat exchanger products that comply with

environmental standards.

5. Global Service Network: ALFA has a global service network,

providing customers with timely technical support and maintenance

services.

Q&A

Q: Can I customize samples of heat exchanger plates?

A: Yes,we welcome sample order to test and check quality.

Q : Can you accept mixed batch of different heat exchanger plates

and OEM service?

A : Yes,we support mixed models and OEM service.

|